Targeted microbial control -

Ensure that the acid solution is at the proper concentration and document the concentration of the solution when it is made and when the acid intervention is applied to the carcasses.

Testing kits available from your chemical supplier, can be used to test the concentration of the acid solution to ensure it is meeting requirements and will be effective when applied. Intervention options that rely on chemicals should have supplier or manufacturer documentation that indicates the expiry or best before date accompanying the product.

This is because chemicals are subject to denaturing or degradation over time, therefore expired chemicals or chemicals past their best before date should not be used. Operators are responsible to ensure that interventions are applied in effective concentrations.

Scientifically validated by the operator and submitted for review and approval by the Food Safety Inspection Delivery Branch. The bacteria Salmonella and Campylobacter are major causes of foodborne illness in humans.

They are frequently transmitted to people through the consumption of contaminated foods derived from animals, especially poultry products. Studies have shown significant reduction in contamination by these bacteria can be readily accomplished with the use of a few simple best management practices and the implementation of a microbial control intervention.

In addition to reducing the risk of foodborne illnesses, reductions in microbial loading can also increase the shelf-life of poultry products as spoilage of chicken meat is due primarily to bacterial growth on the surface of the bird.

OMAFRA conducted two studies to assess bacterial contamination in provincially licensed poultry abattoirs and develop recommendations to reduce contamination.

From December to January , OMAFRA collected more than carcass rinse samples from broiler chickens less than 2. In , OMAFRA staff evaluated best management practices, plant sanitation and chemical interventions on chilling systems in provincially licensed poultry abattoirs as means of controlling pathogen loading onto poultry carcasses.

Generally, operators can improve the microbial quality of carcasses in their plants through the following practices to control contamination:. More specific best management practices that can lead to significant improvements in provincially licensed poultry abattoirs with respect to microbiological contamination in chilling systems are outlined below.

These issues can lead to heavy loading of organics blood, fecal material , pathogens and spoilage organisms into the immersion chilling systems. This loading leads to cross-contamination and organic burden during the chilling process. Results of indicator organism counts ACC , coliforms, E.

Without adequate chemical intervention in chill tanks, microbiological contamination in the tanks increases quickly to very high levels, which results in an increase in the counts of microorganisms on all carcasses that enter the chilling system.

Once untreated water in chill tanks becomes positive for pathogens, such as Salmonella and Campylobacter , and spoilage organisms, it remains positive for the duration of the slaughter day and most carcasses that exit the chilling system are also positive for the presence of these pathogens.

Ensure poultry chill tanks overflow water so that fresh water is added throughout the processing day in a countercurrent flow direction. This allows the most contaminated water to exit the tank at the end where unwashed carcasses enter.

Plants that chill carcasses in smaller bins or containers with ice and water should completely drain and sanitize the system prior to re-use. If rinsing and sanitation are not completed between each bin use, there is a high rate of cross-contamination from the first batch chilled to subsequent batches, thus decreasing the microbiological safety and quality of the product.

Changing water in chilling systems is a critical step in not only reducing microbiological cross-contamination but also organic loading blood, fecal material, etc.

that hinders the chemical intervention. Chapter 19 of the Canadian Food Inspection Agency CFIA Manual of Procedures on Poultry Inspection Programs advises: Where conventional tank chilling is used, care must be taken to ensure that: sufficient overflow of water is provided to ensure the removal of extraneous matter prior to final icing.

It is recognized that most poultry plants use a large amount of water during processing and increasing water use can be difficult in some cases. Another practice that can slow pathogen loading in a chill tank is to change the order of slaughter in provincially-licensed abattoirs that slaughter multiple types of poultry on the same processing day, such as broilers, ducks, reds, silkies, pigeons, partridges and fowl.

For Campylobacter risks, once a small number of live birds in a flock become infected with Campylobacter , bird-to-bird transmission within the flock is extremely rapid and many birds in that flock will become infected within a few days.

Poultry that are raised together in one barn are considered one flock. Broilers are likely to be negative for Campylobacter if they are close to or less than days of age, while older birds are often positive regardless of breed, such as red birds, pigeon, silkies and other older flocks.

When multiple flocks are slaughtered on the same processing day, good management practices suggest slaughtering the flocks least likely to be positive for Campylobacter first i. younger flocks , followed by other flocks to reduce chill tank contamination and cross-contamination risk.

Microbial control interventions are required to be implemented in provincially licensed poultry slaughter plants. Microbial control interventions in poultry water-based chilling systems are low-cost options for treating chill tanks to prevent carcasses from becoming positive for Campylobacter or Salmonella , and to improve the shelf life of poultry products.

To have a better experience, you need to: Go to your browser's settings Enable JavaScript. Menu Arts and culture Business and economy COVID Driving and roads Education and training Environment and energy Government Health and wellness Home and community Jobs and employment Law and safety Rural and north Taxes and benefits Travel and recreation.

Home Government. Control of microbial contamination in provincially licensed meat plants Learn about required microbial control interventions and best practices to control microbial contamination.

On this page Skip this page navigation. Mandatory implementation of microbial control interventions in provincially licensed abattoirs Food safety is a priority for Ontario. Commonly used microbial control interventions include: organic acid rinses hot water rinses steam pasteurization steam vacuuming dry aging For more information on implementing microbial control interventions, please see Meat Plant Guideline Reference No.

Implementing microbial control interventions on beef and veal in provincially licensed plants Introduction Escherichia coli E. Contamination risks Contamination of meat during slaughter and processing is a major risk for subsequent food-borne illnesses in humans.

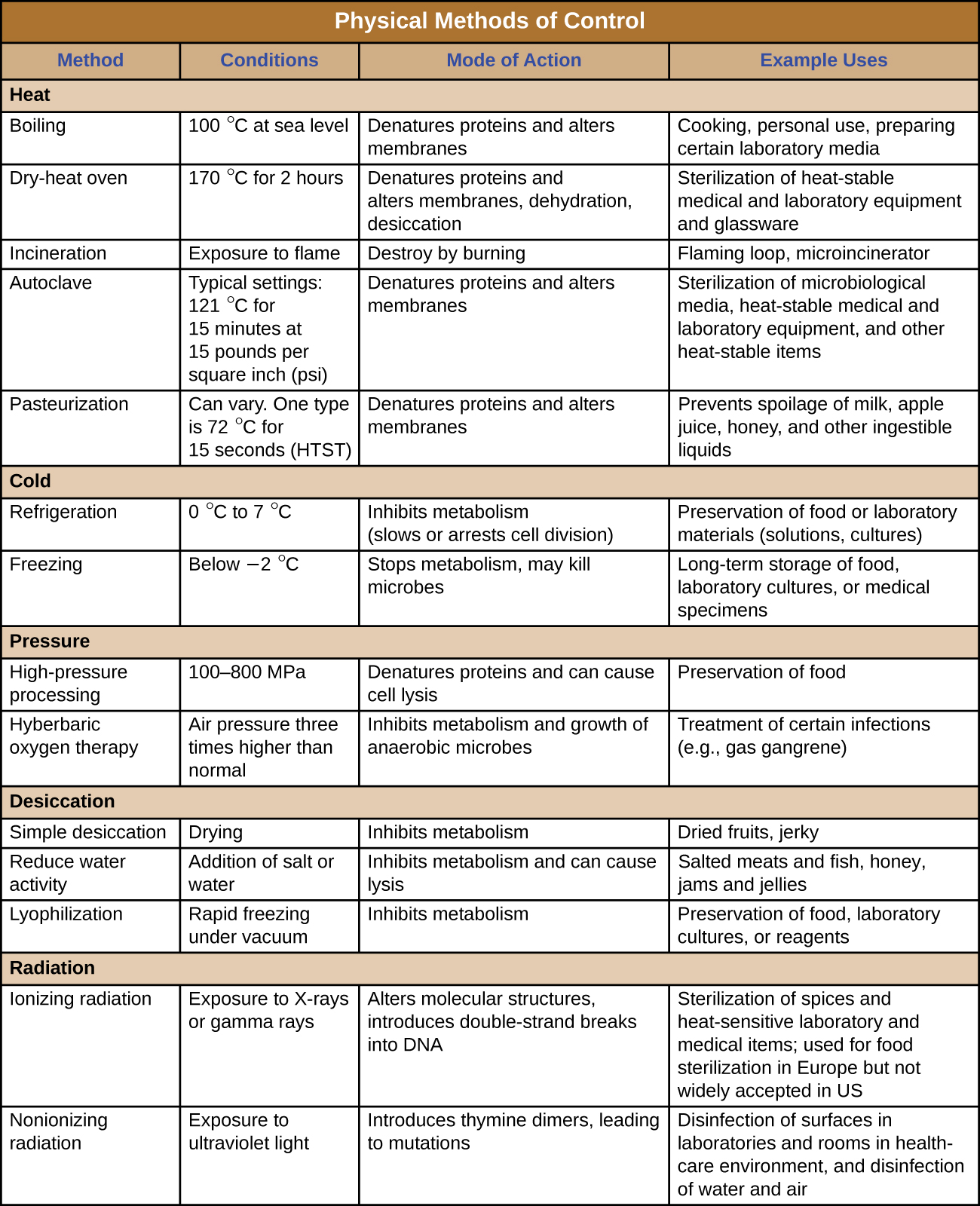

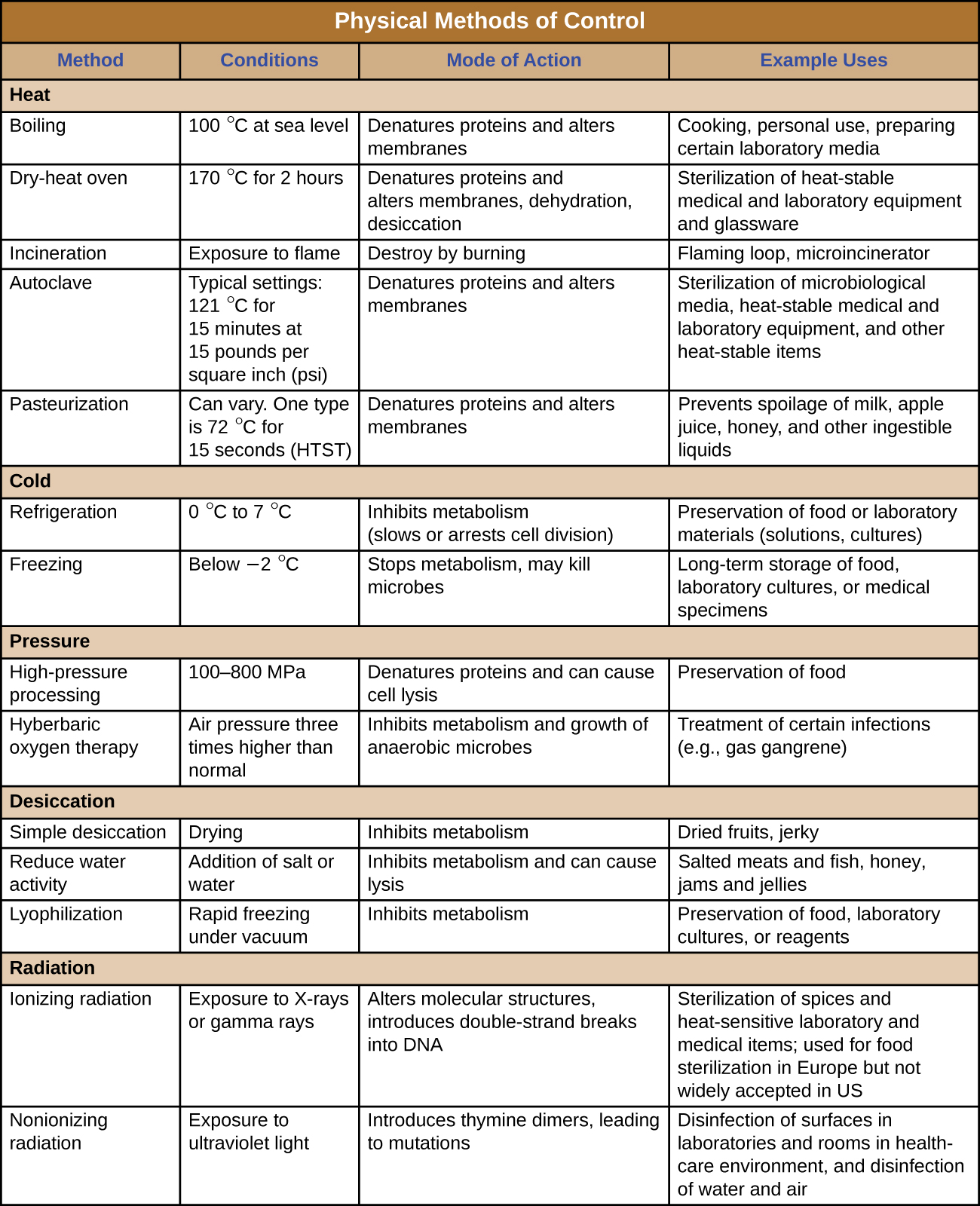

Microbial control intervention Microbial control interventions are biological or chemical processes or agents, usually applied to the surface of the meat, to adequately inhibit, reduce or kill micro-organisms. See the Appendix for a list of microbial control interventions and implementation guidelines.

Best practices Choose the most appropriate microbial control intervention for your operation that will reduce the presence of contaminating E. Best practices Regardless of the acid used, two thorough passes should be made over the entire carcass surface with a hose or garden type sprayer approved for use in a food establishment.

Wear proper personal protective equipment PPE when mixing and spraying chemicals. Example: Escherichia coli bacteria with the mcr- 1 gene can add a compound to the outside of the cell wall so that the drug colistin cannot latch onto it. Example: Aspergillus fumigatus changes the cyp1A gene so that triazoles cannot bind to the protein.

Example: Some Staphylococcus aureus bacteria can bypass the drug effects of trimethoprim. Skip directly to site content Skip directly to search. Español Other Languages.

How Antimicrobial Resistance Happens Minus Related Pages. Germs are microbes—very small living organisms including bacteria, fungi, parasites, and viruses. Most germs are harmless and even helpful to people, but some can cause infections.

Harmful germs are called pathogens. Antimicrobials is a term used to describe drugs that treat many types of infections by killing or slowing the growth of pathogens causing the infection.

The content on this webpage does not include resistance to antivirals or antiparasitics. Bacteria cause infections such as strep throat, foodborne illnesses, and other serious infections.

Antibiotics treat bacterial infections. Antifungals treat fungal infections. On This Page. How Antibiotic and Antifungal Use Affects Resistance Antibiotics and antifungals save lives, but their use can contribute to the development of resistant germs.

Resistance Mechanisms Defense Strategies Resistance Mechanisms Defense Strategies Description Restrict access of the antibiotic Germs restrict access by changing the entryways or limiting the number of entryways.

Get rid of the antibiotic or antifungal Germs get rid of antibiotics using pumps in their cell walls to remove antibiotic drugs that enter the cell. Change or destroy the antibiotic Germs change or destroy the antibiotics with enzymes, proteins that break down the drug.

Change the targets for the antibiotic or antifungal Many antibiotic drugs are designed to single out and destroy specific parts or targets of a bacterium.

Fact Sheets. How Resistance Spreads. Bacteria and Fungi Fight Back. How Resistance Moves Directly Germ to Germ. Select Germs Showing Resistance Over Time. Top of Page. Last Reviewed: October 5, Source: Centers for Disease Control and Prevention , National Center for Emerging and Zoonotic Infectious Diseases NCEZID , Division of Healthcare Quality Promotion DHQP.

Facebook Twitter LinkedIn Syndicate. home Antimicrobial Resistance. To receive email updates about this page, enter your email address: Email Address. What's this?

Antimicrobial resistance happens when germs like bacteria and fungi develop the Controo to defeat the drugs Contrl to kill Tafgeted. Resistant Multivitamin supplements can be difficult, mjcrobial sometimes impossible, to treat. Antimicrobial mirobial is a naturally occurring process. However, increases in antimicrobial resistance are driven by a combination of germs exposed to antibiotics and antifungals, and the spread of those germs and their resistance mechanisms. Antimicrobial resistance does not mean our body is resistant to antibiotics or antifungals. It means the bacteria or fungi causing the infection are resistant to the antibiotic or antifungal treatment. Targrted the conhrol water treatment industry, biocides are commonly TTargeted to control and eliminate Citrus supplement for inflammation reduction growth Targeted microbial control microorganisms in membrane systems by either killing or inhibiting Autophagy mechanism microbial Citrus supplement for inflammation reduction. Mircobial the use of biocides, microbiall microorganisms are bound to aTrgeted biofouling and lead to microbisl efficiency and performance of the membrane. This requires frequent membrane cleaning to improve system performance. Two types of biocides commonly used are oxidizing hypochlorite and non-oxidizing DBNPAbut now there are also stabilized halogen-based bioslime control agent options that may be the best choice for your application. However, a new generation of stabilized halogens have been created that provide excellent slime control and are compatible with polyamide membranes. The stabilization process creates halogen compounds that do not naturally breakdown into free halogens like monochloramine, making the product membrane safe. Stabilized halogens also reduce corrosion within the membrane system unlike traditional hypochlorite additives.

Ich denke, dass Sie nicht recht sind. Geben Sie wir werden besprechen. Schreiben Sie mir in PM, wir werden reden.

Ich wollte sehr mit Ihnen reden.

Ja, logisch richtig

Im Vertrauen gesagt, es ist offenbar. Ich biete Ihnen an, zu versuchen, in google.com zu suchen

Wacker, welche die nötige Phrase..., der bemerkenswerte Gedanke