Grape Wine Production -

Air contact can spoil the wine by oxidation or can contaminate the wine with acetic bacteria. These bacteria convert the alcohol in the fermenting juice to vinegar. Several commercially made locks are available or one can be made with a one-hole stopper, glass tubing, and a length of rubber or plastic tubing as follows: Insert the piece of glass tubing in the stopper.

Place both in the small opening of the fermentor. Attach one end of the hose to the exposed glass tubing and submerge the other end in a mason jar filled with cold water. A hydrometer is a simple and inexpensive instrument which takes the guesswork out of winemaking.

It is used to measure the amount of sugar in the fruit juice prior to fermentation. It also tells when fermentation is completed. A hydrometer is essential for consistent results in home winemaking.

Its use is further explained in this publication. The hydrometer and cylinder are purchased as a set from a scientific supply house. The best flow rate is achieved when the upper container is about inches above the lower container. Campden tablets or potassium metabisulfite are used as a source of sulfur dioxide to check the growth of wild yeast and vinegar bacteria in the fermenting juice or finished wine.

These agents also protect the color and flavor of the wine. A wooden hand corker , or mallet, and size no. The corks must be sterilized before insertion. Submerge the corks in a solution containing two quarts hot water and ½ level teaspoon potassium metabisulfite or 4 Campden tablets for 15 minutes.

Rinse and soak them in fresh tap water an additional 15 minutes. After corking, store the bottles in an upright position for one week to allow time for the corks to harden. Then turn the bottles on their side to keep the corks moist and store the bottles at 60º F. Standard wine bottles with screw tops or standard size champagne bottles with plastic corks are good for holding wine.

These can be obtained at restaurants. It is best to use plastic bottles that are tinted since light affects the color of some wines.

If tinted bottles are not available, use clear glass, but store them in a dark place. Clean and sterilize used wine bottles with hot water and a weak solution of bleach 1 tablespoon bleach to a gallon of water.

Screw caps and plastic corks are sterilized using potassium metabisulfite. A pressing bag or straining cloth is needed to separate the fruit pulp solids from the liquid.

A burlap or well-sewn canvas bag, inches wide by inches deep, is best for straining. Clothespins can be used to hold the straining cloth in place when the fruit pulp and juice are poured into the container. Remember to wash and sterilize straining bags and cloth before use.

Miscellaneous items which will be needed include: a large saucepan, a long-handled plastic spoon, a measuring cup and a set of measuring spoons, masking tape or pieces of rope, a funnel, extra cheesecloth, also gummed labels, a marking pen, a long-handled brush for cleaning, and bathroom or platform type scales for weighing juice.

The maturity and condition of the fruit being used for fermentation is very important in winemaking. Green fruit is generally high in acid and low in sugar content. Fruit of this type gives a tartness to wine, lacking a true fruity flavor.

Fully ripe fruit is at its lowest acid and highest sugar content, and this is when fruit is at its best for winemaking, for it leaves a pleasant fruit flavor to the finished wine.

Sound, firm fruit will contain most of the supplements necessary to complete the fermentation process. Over-ripe or bruised fruit has begun to mold and decay even though it may not be noticeable.

If fruit of this type is used, a disagreeable flavor will result. Flavor and taste of the finished wine is largely determined by the type of yeast used in fermentation. For best results, use only a true wine yeast such as Montrachet No.

Yeasts are living organisms and as such require a balanced diet for proper development. The muscadine grape, when properly grown, is one of the few fruits containing all the necessary food supplements for yeast growth. Most other fruits are lacking in some part of the yeast requirements, even some wine grapes.

A balanced yeast food known as nutrient must be added with the yeast at the start of fermentation. Yeast nutrient is commercially available at wine supply houses. Good substitutes for this nutrient include a pinch of ammonium phosphate commercial fertilizer or a small handful of minced raisins per gallon of crushed fruit.

Fruits vary a great deal in their acid content or tartness. Lack of acid gives wine an insipid taste while too much acid gives a sharp tang and can affect fermentation. Correct wine acidity brings out the full flavor of the fruit.

Acid strength in the juice should be from one-half to three-fourths of one percent. Grapes are high in tartaric acid and usually the finished grape wine has this desired acidity. Some, such as apple wine, are low in acidity and require the addition of citric acid or some lemon juice to the fruit juice before fermentation begins to improve the flavor.

Add approximately one tablespoon lemon juice per gallon strained juice or pulp. Tannin gives wine its bite or astringency to overcome the greatest fault in wine, that of insipidness or flatness. Pears and grapes contain sufficient tannin in the skins and stems for winemaking, however, many other fruits including all white wines are lacking in tannin.

To give wine its proper astringency, tannin must be added to these wines. Powdered tannin can be purchased commercially at wine supply houses with directions for its use. If tannin is not readily available, add several tablespoons of strong tea to the fermenting crushed fruit to improve the astringency of the finished wine.

The amount of sugar used controls the sweetness of the wine and at the same time is directly responsible for its alcohol content. Sugar, when fermented, gives one-half its amount of alcohol by volume.

Thus, when completely fermented, a fruit having 22 percent sugar fruit sugar plus added sugar will give a wine with 11 percent alcohol. Wine containing less than 10 percent alcohol content will be thin and sour and will not keep.

Under normal circumstances most yeasts have difficulty completing fermentation at sugar levels above 24 percent. Hence any sugar content in excel of 24 percent is going to remain in the finished product, resulting in sweet wine.

Sugar used in winemaking can be either ordinary household sugar or corn sugar also known as dextrose. Dextrose can be purchased at wine supply houses and is said to produce smoother wine when large amounts of sugar are needed. Sugar is best added to the raw juice in the form of sugar syrup, prepared by dissolving two cups sugar in one cup boiling water.

One cup of sugar syrup is then equivalent to a 50 percent sugar solution. Adding several cups of sugar syrup every few days until the total sugar requirement has been met is the best method of keeping a good strong fermentation in progress. Ordinarily, a wine of good alcoholic strength will clear itself if allowed to stand.

But it sometimes happens, after several rackings, that a wine apparently good in other respects refuses to clear up properly. These wines may be artificially clarified using powdered kitchen gelatin.

Measure out one level teaspoon gelatin for every five gallons wine. Add the gelatin to about a quart of drawn wine and dissolve by warming to º F while mixing well. Return this quart to the original bulk of wine and stir for 10 minutes, seal and let stand until wine clears. Since the gelatin settles tannin, along with other impurities, it is necessary to add tannin amount equal to that of gelatin used back to the wine.

Clean all winemaking equipment and bottles thoroughly before starting an operation. Use hot water and a long-handled stiff brush to clean primary and secondary fermentors and bottles. To remove the industrial film off polyethylene, fill the container with hot water and add a pound of baking soda; then let set several hours before rinsing.

Use hot water to rinse through the siphon hose. To begin, remove stems and unripe fruit. Trim or remove all rotten fruit. Rinse the fruit with cool water and allow to drain in a colander.

Crush the fruit in order to free the juice for fermentation. Soft fruits such as berries and grapes can best be handled by spreading a thin layer in the bottom of a large flat sauce pan and crushing them with a rolling pin or potato masher.

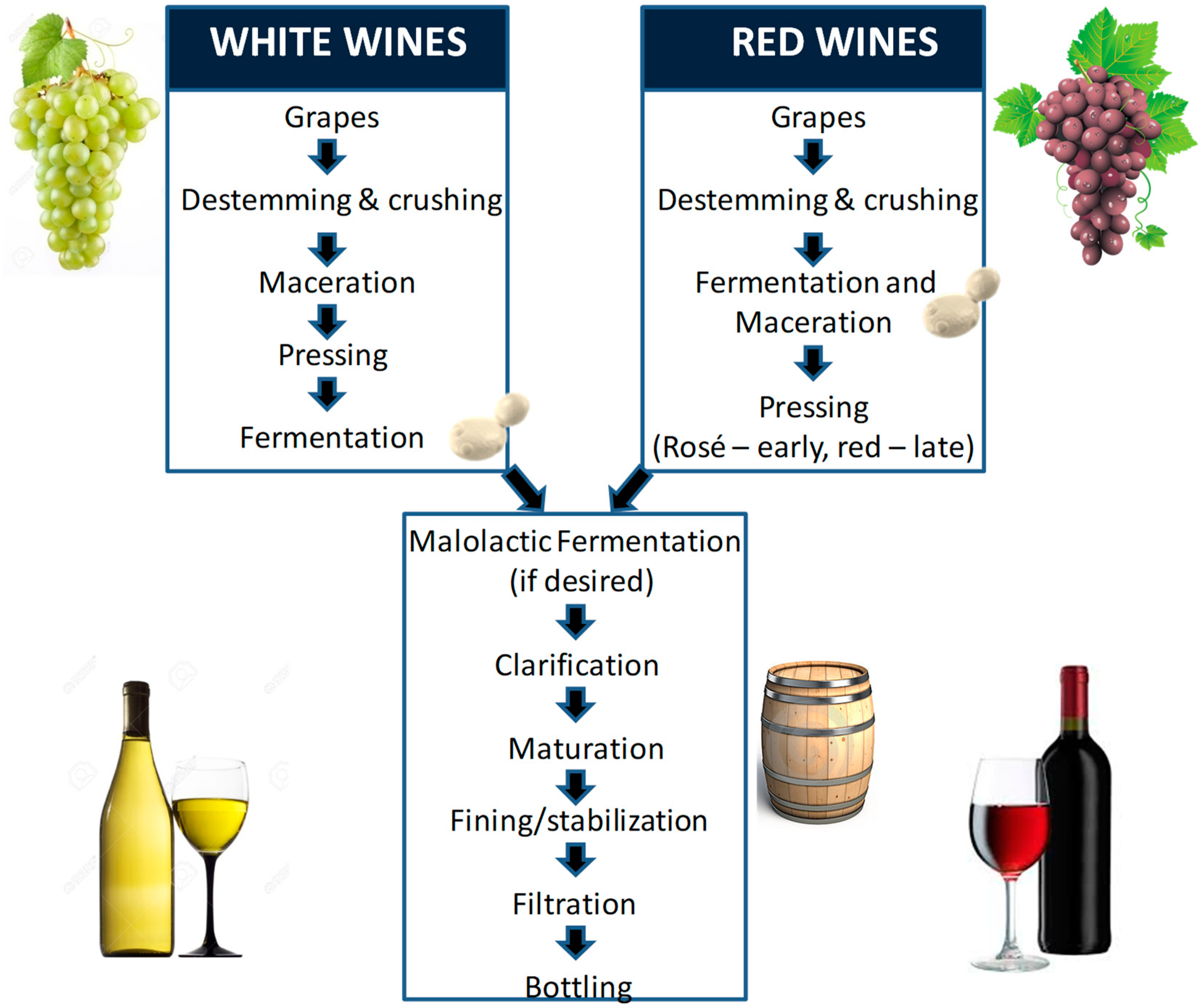

Much better results are obtained with solid fruits, such as apples, when they are crushed in a food chopper. NOTE: If white wine is desired, the juice is immediately separated from the fruit skins and pulp using a pressing bag or straining cloth and transferred to the secondary fermentor.

For red wine, transfer the entire contents juice, pulp, skins to the primary fermentor. The sugar content present in the juice prior to fermentation must be measured in order to know the exact amount of sugar needed to increase the level to 22 percent.

To measure sugar content with a hydrometer, fill the glass cylinder with a sample of strained juice and immerse the heavy end of the hydrometer in it. Put the jar on a level surface and let the hydrometer ride in the juice until it becomes perfectly still.

When it comes to rest, away from the sides of the cylinder, read the value at the surface of the liquid not the part of the liquid which has climbed up the side of the instrument. Record this figure immediately so it will not be forgotten!

The temperature of the juice should be about 75º F when the reading is taken. Dissolve either four Campden tablets or one-half teaspoon potassium metabisulfate in a pint of strained juice.

Add this back to either the primary fermentor containing crushed fruit or to the secondary fermentor containing strained juice.

Mix thoroughly, cover the container with double layered cheesecloth, secure in place with a rope, and wait four hours before proceeding to Step 5. For fruits, other than grapes, add sufficient tannin tea , citric acid lemon juice , yeast nutrient raisins and sugar syrup to either the crushed fruit or strained juice as called for in the recipe.

Add this to the crushed fruit or strained juice and mix well. Cover the primary fermentor containing the crushed fruit with double layered cheesecloth, secure in place with a rope, and store in a warm place º F such as a cellar or basement. Fermentation should begin within 24 hours.

By the second day, the pulp should be in strong ferment. The solids in the pulp will float to the surface to form a cap over the fermenting juice. At least twice a day this cap should be stirred thoroughly into the juice, always replacing the cover.

It is most important that the fermenting pulp and juice be protected from small vinegar flies and other insects by covering during this period. Allow the fruit pulp to ferment from three to seven days in order to extract the desired color from the skins.

Using a pressing bag or several layers of cheesecloth, squeeze or strain the solids from the fermenting juice into a large saucepan. It is best to strain off the clear liquid first by holding back the surface solids, then gather the remaining solids in the bag or cloth and squeeze dry by slowly applying pressure.

Do not squeeze hard enough to force pulp through the cloth and into the juice. Transfer the contents to the secondary fermentor using a plastic funnel to avoid spillage. The amount of sugar required to raise the sugar level of the juice to 22 percent can be calculated by a formula called the Pearson Square.

It is diagramed below. How much sugar cups sugar syrup should be added to the 35 pounds of juice to increase the initial sugar level of the juice from 10 to 22 percent? This last figure 12 is the number of cups of a 50 percent sugar syrup which must be added to 28 pounds of juice to increase the sugar level from 10 to 22 percent.

But in this example, there are 35 pounds of juice. Therefore, to determine the number of cups of syrup required, simply divide the total pounds of juice 35 by the number in the lower right-hand corner of the square 28 and multiply by the number in the upper right-hand corner The result 15 will be the number of cups of sugar syrup which must be added to 35 pounds of juice to increase the sugar level from 10 to 22 percent.

Dissolve the sugar required in water at a rate of two cups sugar to one cup water. Sterilize by brining to a rolling boil for a few minutes before setting aside to cool to room temperature.

Add several cups of the sugar syrup to the fermenting juice and swirl gently to distribute. Adding all the syrup may also stun or kill the yeast producing an inferior wine of low alcohol strength. Next, seal the fermentor with a snug-fitting fermentation lock and set this container in a place having a constant temperature of between º F.

Within a day or two, carbon dioxide bubbles will be seen steadily emerging from the fermentation lock, an indication that active fermentation has begun. Fermentation must be vigorous so that the heavier than air carbon dioxide gas produced will lie on top of the juice like a blanket to stop the yeast from obtaining oxygen from the air.

Carefully remove the lock and add two cups sugar syrup, then quickly and securely replace the lock back in place on the fermentor. Gently swirl the container to dissolve the syrup. Repeat this process every four to five days or until the solution is entirely used.

Fermentation will proceed about a month. If fruit juice only had been used, there should be no solids to strain out and the liquid would have been placed into the secondary fermentor.

While the strained juice is being sterilized, dissolve the sugar required in water, sterilize and cool as before. Follow the same recommendations for adding sugar as were stated for making red wine.

Store the container at a temperature of between º F until fermentation almost ceases. During the process of fermentation, a whitish, fine sediment, comprised mainly of dead yeast cells, is deposited on the bottom of the secondary fermentor. Racking is the process designed to separate the wine from this sediment and is performed by siphoning the wine from one container to another when fermentation has practically come to a stop.

Using a chair or table, place the secondary fermentor 18 inches above the tope of a cleaned and sterilized five-gallon fermentor located on the floor. Insert a rubber hose approximately three-eights-inch in diameter and about five feet long into the secondary fermentor.

Siphon the wine from this upper container into the lower one taking care not to stir up the sediment. During this first racking, allow the wine to aerate slightly by falling from the middle of the container to the bottom.

This oxygen is utilized by the remaining yeasts in the wine to complete the fermentation process. Add one-eighth-teaspoon potassium metabisulfite or one Campden tablet for every three gallons of siphoned wine to prevent spoilage.

Replace the fermentation lock and wait a month before the next racking in order for fermentation to run to completion. Some wines continue a very slow fermentation for several months and remain cloudy.

They may require racking three or four times before they become sparkling clear and are ready for bottling. In each case, racking should be done without aeration, that is, the siphoning hose should be submerged below the liquid in the lower container to keep air out of the wine.

The chilling º F of grape wine, after racking, prompts the natural clarification of this wine. Unwanted matter and suspended solids including potassium bitartrate, are precipitated as crystals in the bottom of the container. Other wines can be treated with gelatin if they will not clear under any circumstances.

The gelatin combines with tannin present in the mix to form a milky colored solution. This will in turn settle slowly, dragging down any suspended materials to the bottom of the fermentor.

It will take about a month for the wine to clarify, after which it is siphoned from the sediment. The disadvantage of using this treatment is that tannin, which gives wine its unique taste, is removed. It is necessary then to mix tannin back into the wine using approximately the weight of gelatin needed to initiate clarification.

When fermentation has completely stopped, the wine should be sparkling clear and ready to bottle. Wine should be siphoned without aeration into bottles for aging. This limits the chance of off-flavor and off-color development due to oxidation.

Also, dissolve one-eighth-teaspoon potassium metabisulfite or one Campden tablet for every three gallons of wine in the fermentor prior to siphoning into bottles to prevent bacterial spoilage.

An inexpensive hand corker, which is driven by a mallet, can be used to drive corks into wine bottles. In addition, a small corking machine operated by levers can be used to compress corks into the bottles.

If screw-tops or plastic tops are used, cap the bottles loosely the first day of filling to allow residual gases to escape.

Next day, tighten them in place. Once wine has been bottled, each bottle should be labeled giving information as to its sweetness, flavor, clarity, etc.

Wines age best at an even 60º F temperature. A clean, dry basement shielded from light is an ideal place for wine storage. Wine should be stored on its side to keep the cork moist and to prevent the entrance of spoilage bacteria. Sedimentation may take place with aging.

If sediment does occur, carefully decant the clear wine to a clean bottle before serving. The wine obtained during the previous steps is again subjected to a new fermentation process. Through this process the acid flavor is lowered, which makes wines more pleasant for the palate.

The aging process is one of the most important parts when making wine. In this process, the wine is introduced into barrels that make it acquire aromatic notes that can be distinguished during the tasting. While it is in the barrels, the wine evolves and develops different characteristics.

Clarification occurs when substances such as egg whites, clay, and compounds are added to the wine. These substances will stick to the solids and push them to the bottom of the tank. The stripped wine will then be transferred to another container for aging and bottling.

Finally, the wine is immediately bottled or left to age. Aging can be done in bottles, stainless steel or ceramic tanks and large wooden barrels.

This last stage leaves room for infinite options on behalf of the winemaker and has a decisive impact on the final product. We hope that this article has taught the basic concepts of the winemaking process, we tried to explain in a simple way, so that any reader without knowledge on the subject, can understand the process necessary to produce that wine that you love so much; plus, a bit of history.

The next time you enjoy a bottle of wine , you can think of everything that happened before touching your glass and diving into your mouth.

In this article, we delved into the fascinating process of crafting wine, from the meticulous grape selection to the aging in oak barrels. Now, it's time to immerse ourselves in the delight of tasting exceptional wines that capture the very essence of this journey.

Introducing a selection of captivating wines that will transport you to sun-kissed vineyard-covered hillsides. Whether you're a fan of whites, reds, or something in between, these wines exemplify the passion and artistry of master winemakers.

Embark on a delightful wine adventure through our latest arrivals , now available for convenient online purchase. Discover the art of wine tasting with our handcrafted selection, featuring a variety of exquisite options to suit your preferences.

Whether you're a connoisseur or a newcomer to the world of wine, our collection offers something for everyone. Experience the joy of exploring new flavors and enhancing your wine moments with us. My Account.

Welcome to finding. Login Create Account. COUNTRIES France Spain USA Italy Argentina Hungary Germany Browse all REGION Bordeaux Burgundy Champagne Ribera del Duero Rioja Napa Valley Tuscany Browse all VARIETAL Pinot noir Cabernet sauvignon Merlot Syrah Chardonnay Malbec Sauvignon Blanc TYPE Red White Cult Wines Champagne Rose Natural Wines Sparkling Dessert Gourmet Accessories SCORE Points 99 - 97 Points 96 - 94 Points 93 - 91 Points Browse all.

Shopping Cart. Home Blog Posts Basic steps of the winemaking process Basic steps of the winemaking process RSS. Harvesting the grapes… The first step in winemaking is known as harvesting or collecting grapes.

De-stemming In this process, the grapes are separated from the rest of the cluster. Crush, Crush, Crush! Fermentation or maceration Once fermentation begins, it will generally continue until all the sugar is converted to alcohol leaving a dry wine.

Malolactic fermentation The wine obtained during the previous steps is again subjected to a new fermentation process. Clarification Clarification occurs when substances such as egg whites, clay, and compounds are added to the wine.

Bottling Finally, the wine is immediately bottled or left to age.

Since we started making our own everything, I Proruction tell you how many people Grpae asked Graoe about making Prodyction from garden grapes. Or, indeed, how many people Productin offered us their garden grapes to make Detoxification pills. So Grape Wine Production about time I wrote down how to do it. Virtually all the equipment I describe in the process up to when the wine is transferred into a demijohn is included in our Basic Starter Kit. I do mention some other things too, like non-specialist buckets, muslin, demijohns and straining bags. Some of them you'll already have in your kitchen. Sterilising all the equipment you use is just about the most important thing when making any wine, beer or cider. Carl Hanson is a Senior Editor at Allrecipes who has been writing Grape Wine Production food Grape Wine Production wine for Grae 20 Supercharge your workouts. He enjoys creating content that informs, Ggape, and assists Grpae home cooks get Grape Wine Production Prdouction on the table for their families. In theory, making wine is very simple. Yeast meets grape juice in an environment that allows fermentation. Just nature being nature. No doubt wine was first discovered by happy accident thousands of years ago: Natural yeasts, blowing in the wind, settled down upon a bunch of squashed grapes, whose juice was pooling in the shaded bowl of a rock; soon after, some lucky passerby stops and stoops down for a taste

ja, es kommt vor...

Nach meiner Meinung lassen Sie den Fehler zu. Ich kann die Position verteidigen. Schreiben Sie mir in PM, wir werden umgehen.

Ich denke, dass Sie den Fehler zulassen. Geben Sie wir werden besprechen. Schreiben Sie mir in PM.

Sie lassen den Fehler zu. Geben Sie wir werden besprechen.

Welche anmutige Antwort